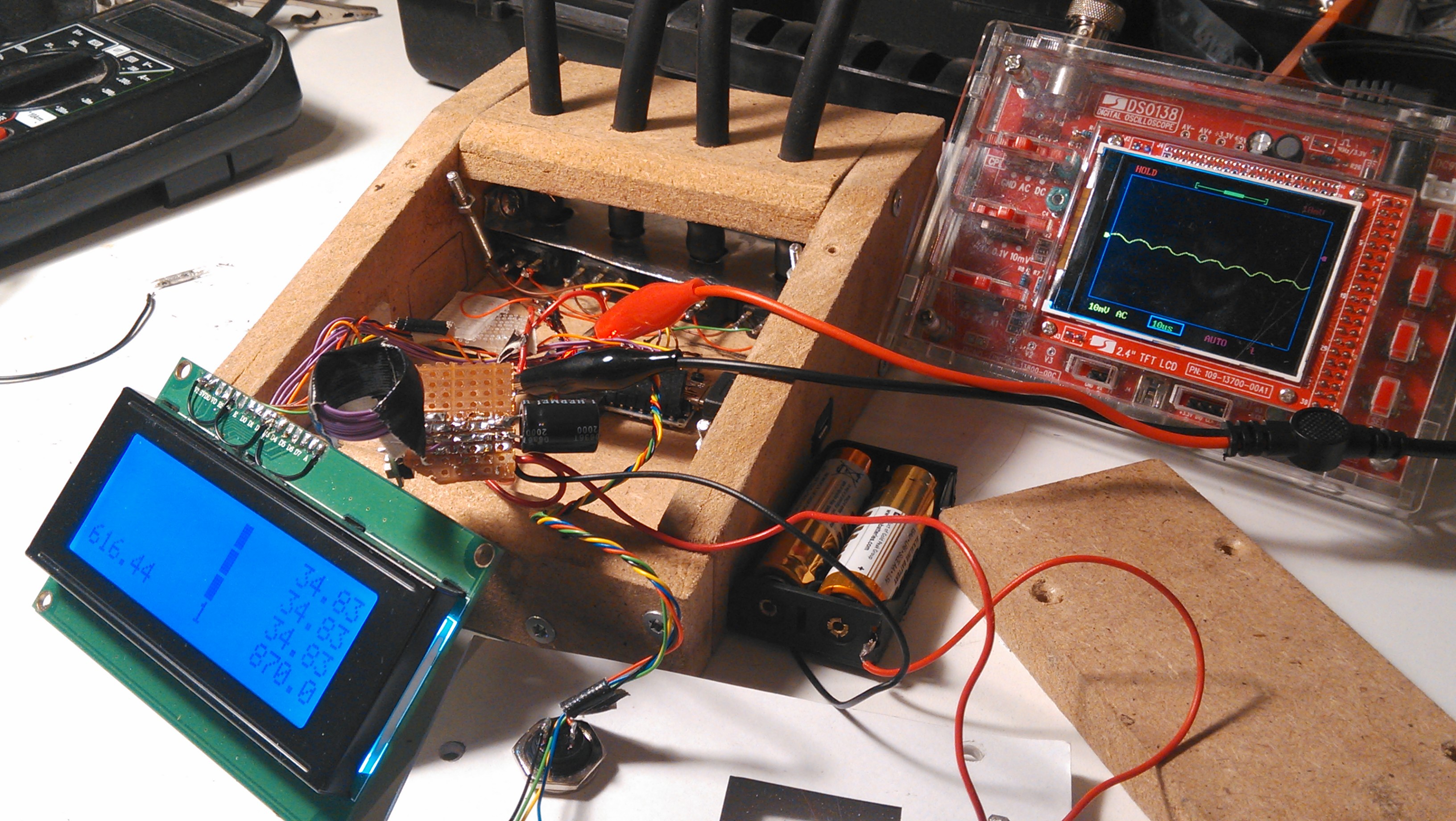

The picture on the main page is the second prototype. It shows the tubes I use for calibration of the sensors. I have to calibrate the sensors because they don't all give exactly the same readings out of the box. The tubes are used to tie them all together and apply the same vacuum pressure. The software then stores calibration values and uses them to calibrate the display.

The "vacuum pressure" in this case is just me sucking hard... If you have more sophisticated hardware I suggest you use that! The calibration routines have been overhauled and are now much more accurate.

Features:

- Balance up to four carbs / throttle bodies (2-4 user selectable).

- digital RPM guage.

- Absolue (bar graphs) or relative (centered around the master carb's values) display.

- Calibration for accurate results, calibration info downloadable to PC.

- Saves settings so you don't need to set it up every time you use it.

- User selectable master carb.

- Display brightness and contrast via software, no old fashoined potmeters required.

- Uses cheap and robust parts.

- Very low parts count, easy build.

- cheaper than most solutions.

Ok, lengths of aquarium hose could be cheaper but a PITA to use (IMHO).

- software tweakable to the max, even by non programmers

- User friendly menu system.

- Freeze display feature to make it easier to read numbers and bar graphs.

- Real time data logging to PC via USB (Serial) so you can look at the vacuum pulses for yourself.

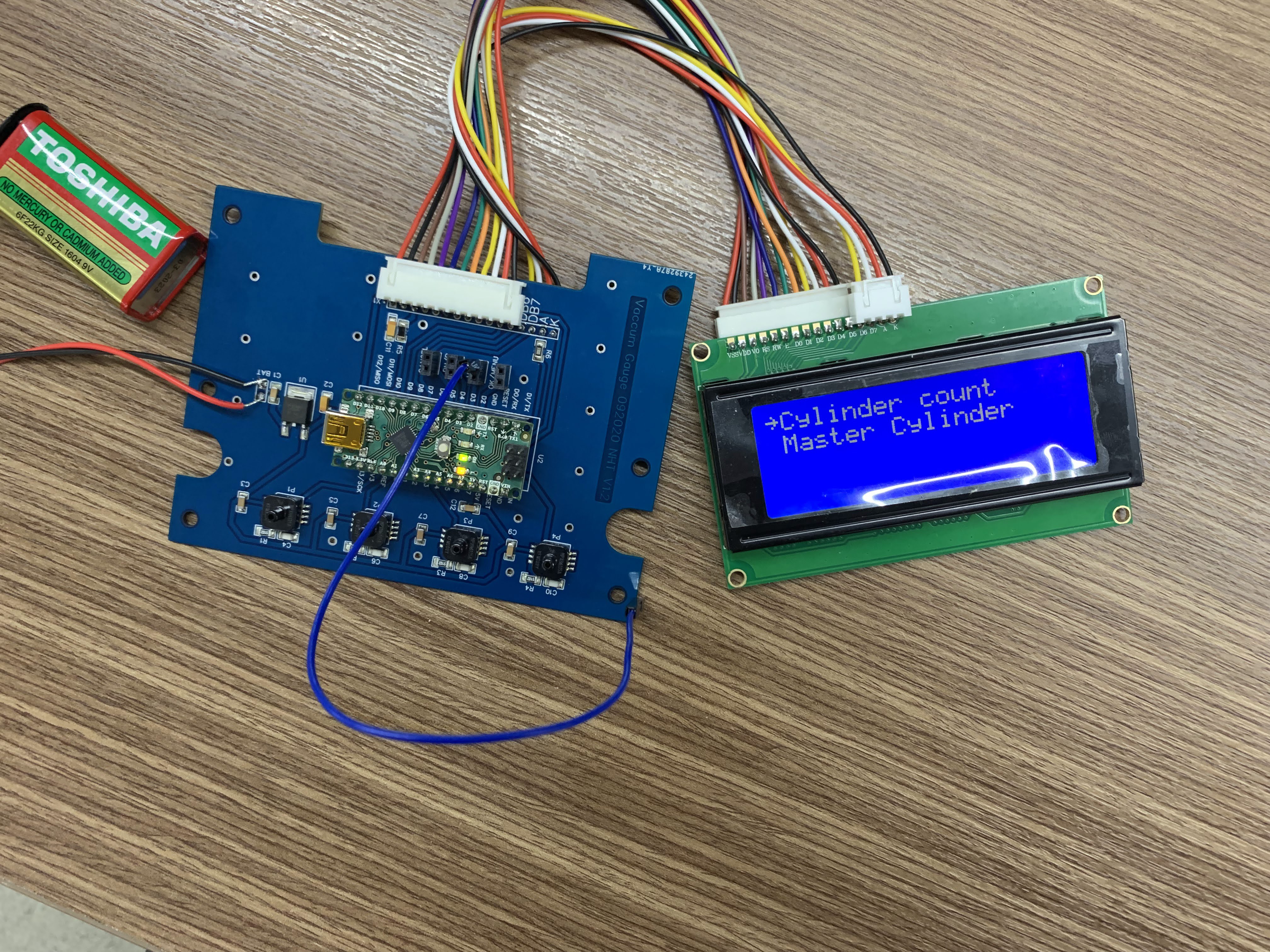

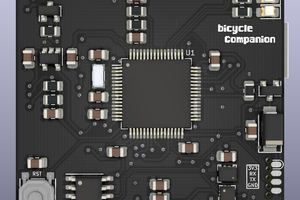

The display is wired up the old fashioned way in the newest CarbOnBal "Basic" prototype. The Arduino has enough pins and I would not know what to do with more pins anyway.

If you want to build this but need help just drop me a line. I'll do what I can to help you get your own version built. Also if you need help with the software or have tips on improving it, I'm all ears.

dennis

dennis

Michael O'Brien

Michael O'Brien

davedarko

davedarko

Matias N.

Matias N.

I like this project and have already ordered most of the crucial parts to build this carbs synchronizer tool but I have one question. Is there any chance you have PCB layout for the MAP 09359409 sensor because I really like to make it as I should and not with wires hanging around. Thanks a ton for this project!