The Nuka Cola PC case came about as I was looking to build a Fallout 4 themed case for Quakecon 2016. I came upon a model for a Nuka Cola Vending Machine on Thingiverse.

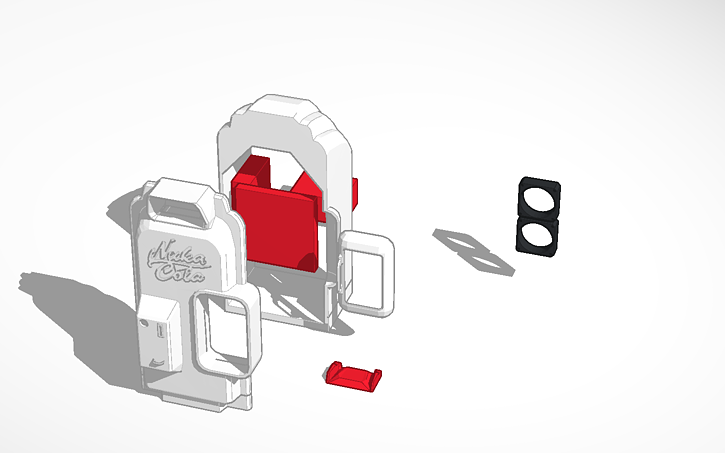

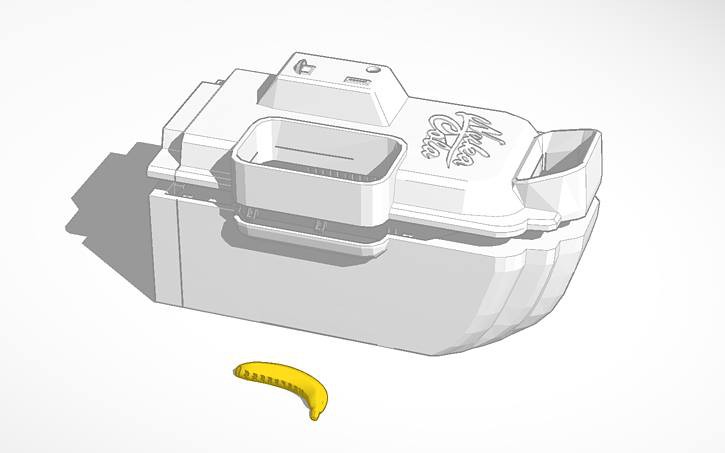

I did a lot of work in TinkerCAD figuring out the scale with my existing mini-ITX form factor PC parts. I sliced it up into 3D printable sections. I decided that laser cutting the mid and back panels with acylic would let me account for mounting holes for components quicker than entirely 3D printing the case.

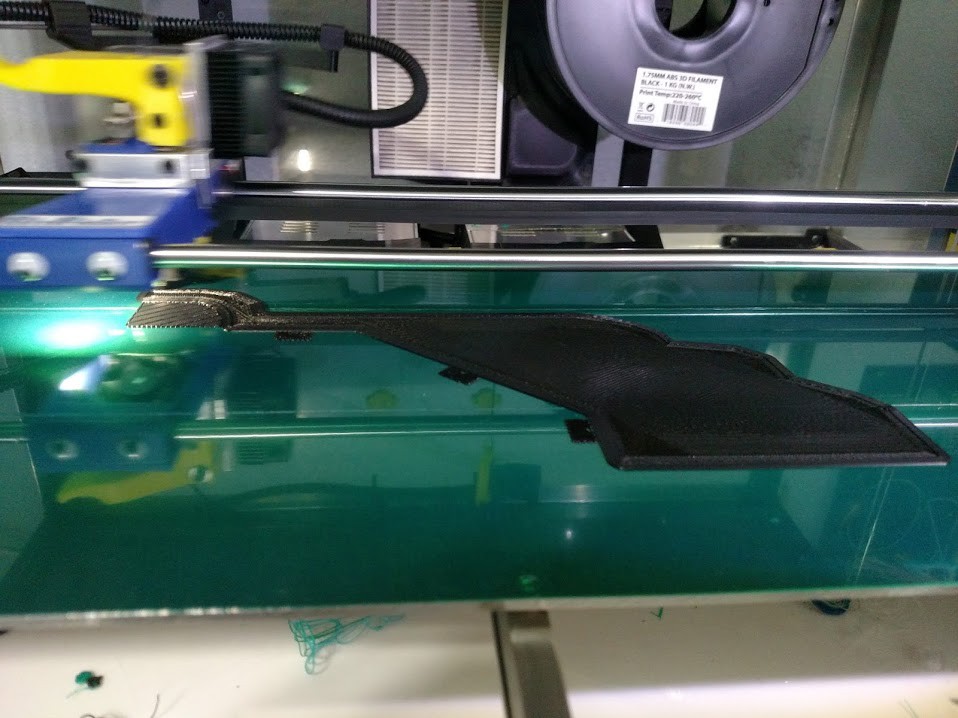

I printed the parts on a PolyPrinter 508. It's a large fast ABS printer made locally.

After printing all the parts, I glued the parts together with CA glue and clamped them to make sure it didn't have many gaps.

After printing all the parts, I glued the parts together with CA glue and clamped them to make sure it didn't have many gaps.

I designed tabs with 4mm holes to press in brass M3 threaded inserts to screw in the acrylic panels. I then did several test cuts to make sure the holes were aligned.

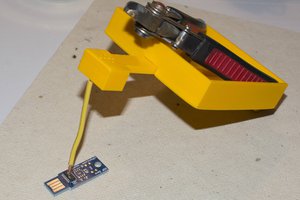

The front panel completed:

I had didn't use hardener with my bondo which made a mess. I ended up scraping it off, then sanding the entire thing with 180grit sand paper to smooth it down. I used Tamiya modeling putty to fill in the gaps and some of the 3D printing artifacts.

Used automotive primer to prime it for it's base coats.

The Lab Guy

The Lab Guy

Brian Brocken

Brian Brocken

conorpp

conorpp

How structurally sound is the whole case? How big of a bump does it need to break?