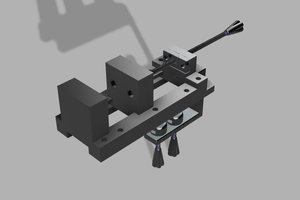

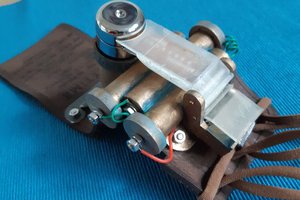

This 3D printed bench vise has a lot of exchangeable parts which can be modified by the user or replaced in case of a failure or breaking.

The printing parameters of this 3D printing are as follows:

- Standard resolution: 0.2mm

- Infill: 15% triangles

- Wall thickness: 0.8 mm

- Wall line count: 2

- Print speed: 50-60 mm/s

- Total printing time: 31h 51min

- Total weight: 258g

Parts:

1) Body

Printing time: 12h 52min

Weight: 108g

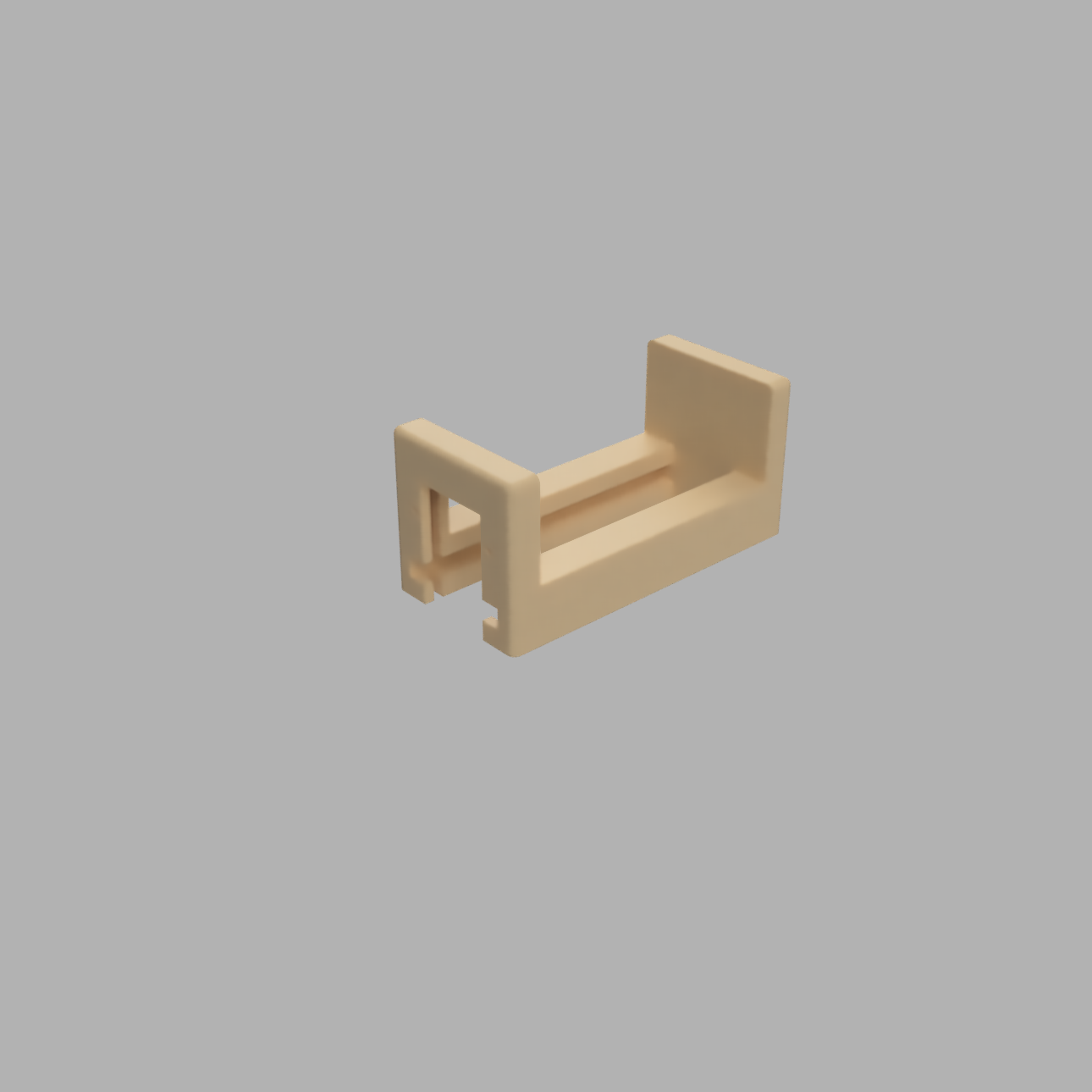

2) Base

Printing time: 4h 48min

Weight: 44g

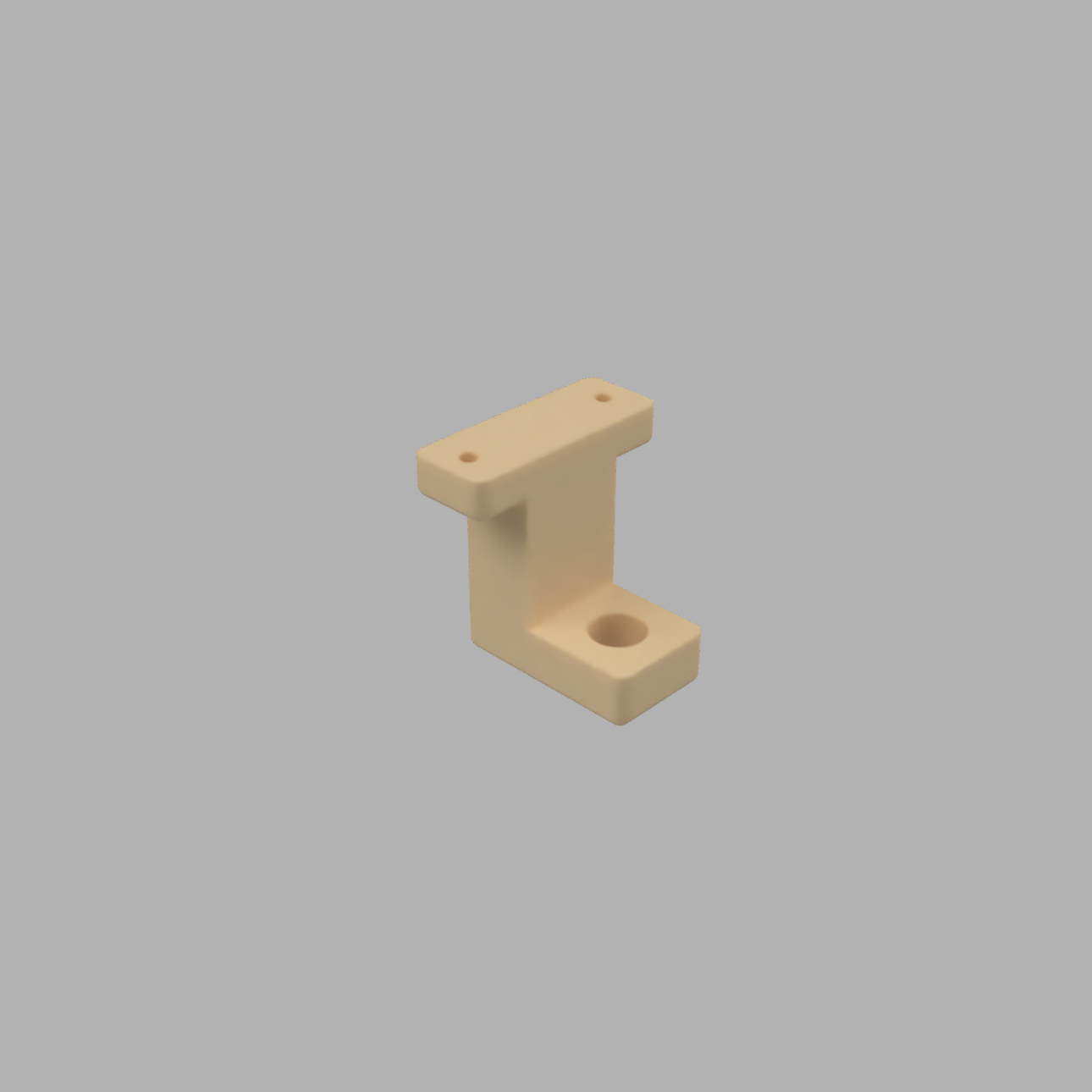

3) Wall

Printing time: 2h 12min

Weight: 21g

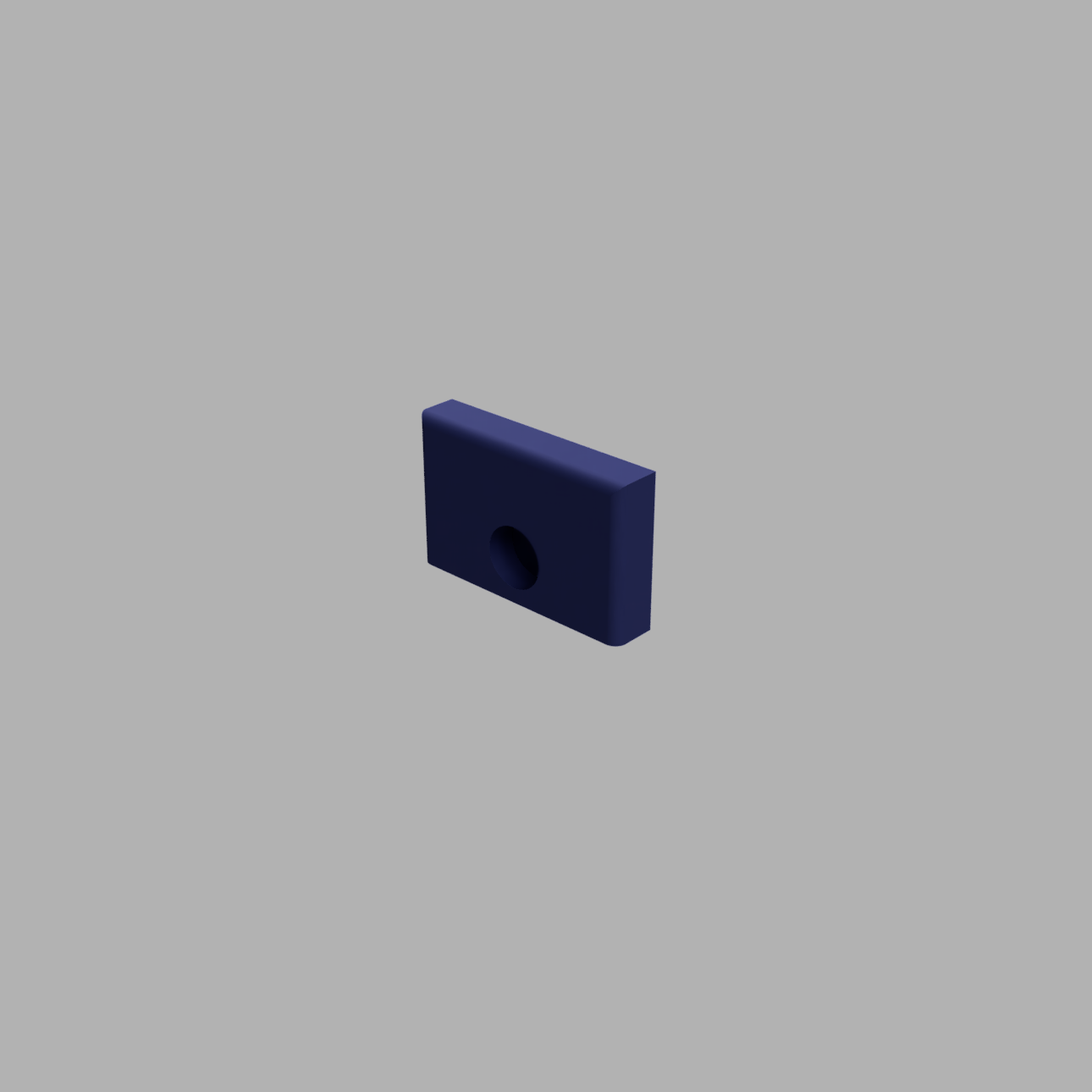

4) Face x2

Printing time: 2h 33min

Weight: 23g

5) Pin

Printing time: 1h 8min

Weight: 8g

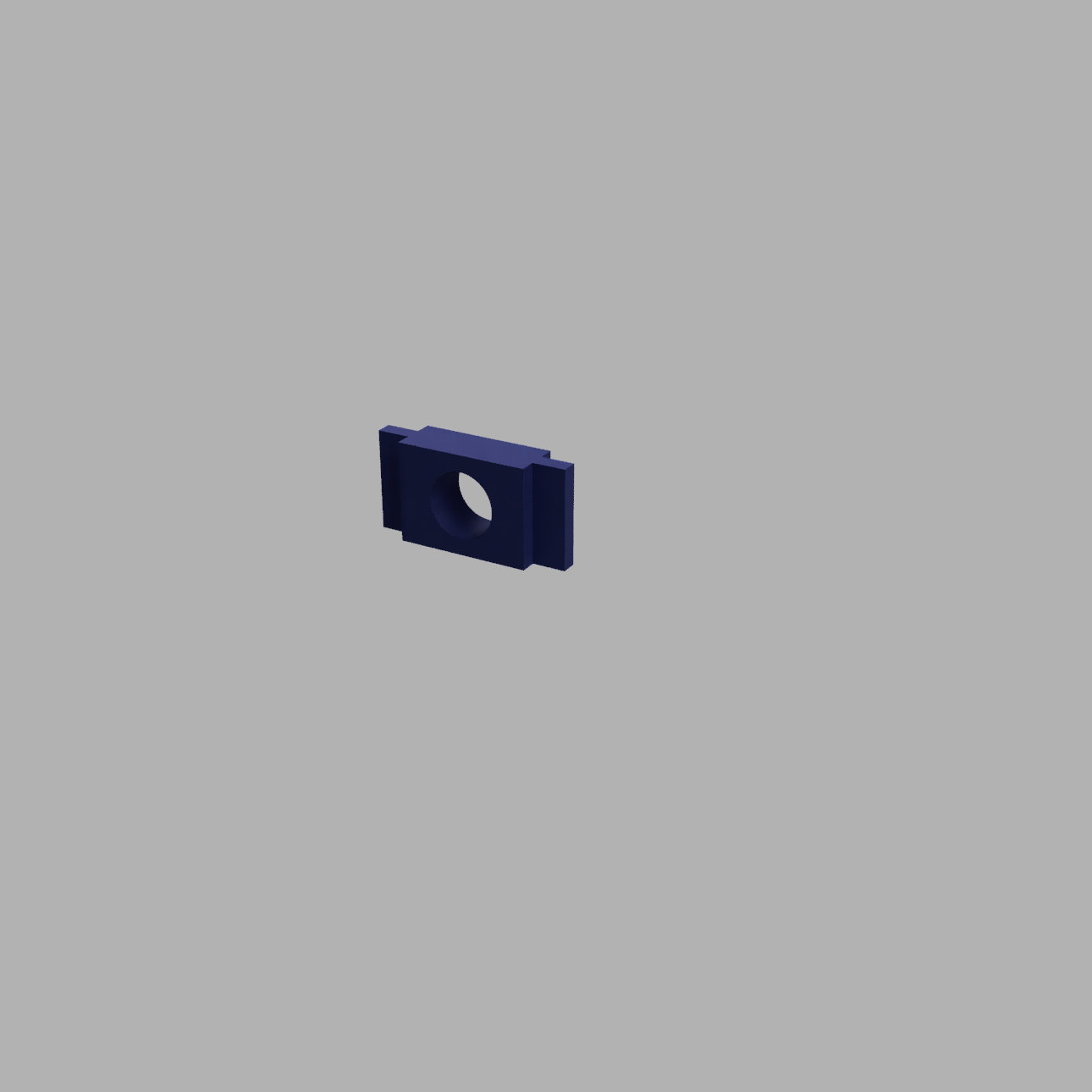

6) Slider

Printing time: 1h 35min

Weight: 15g

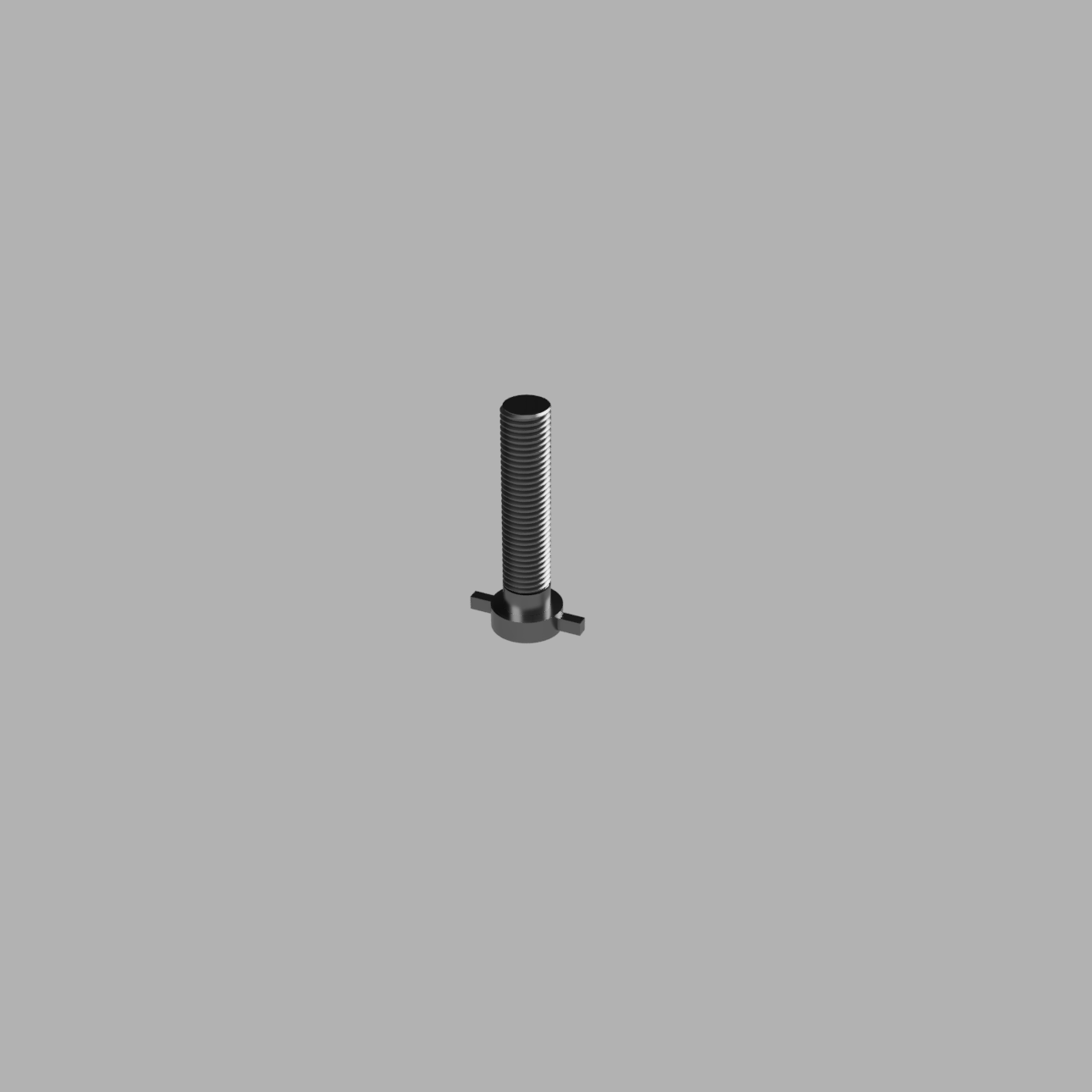

7) Screw 1

Printing time: 4h 12min

Weight: 24g

8) Screw 2

Printing time: 2h 31min

Weight: 15g

joaquin dassori

joaquin dassori

Michał

Michał

Bram

Bram

Robert Mordzon

Robert Mordzon