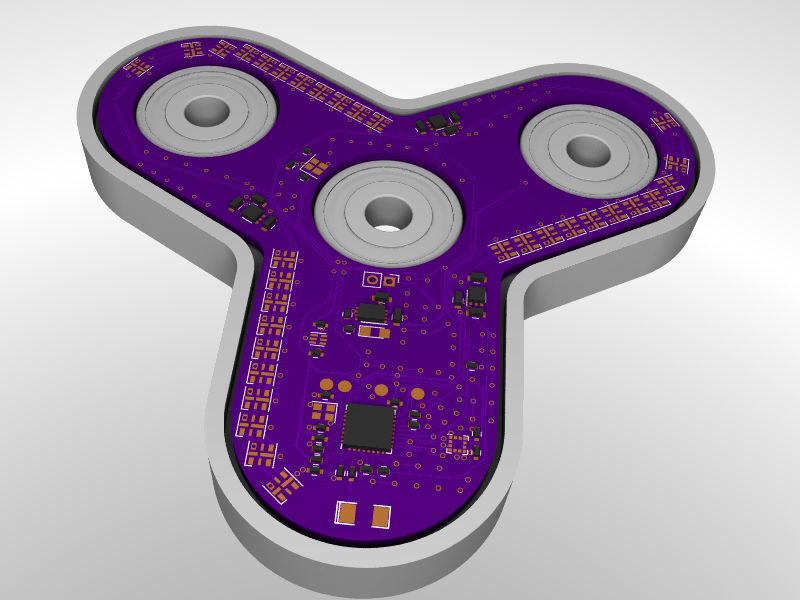

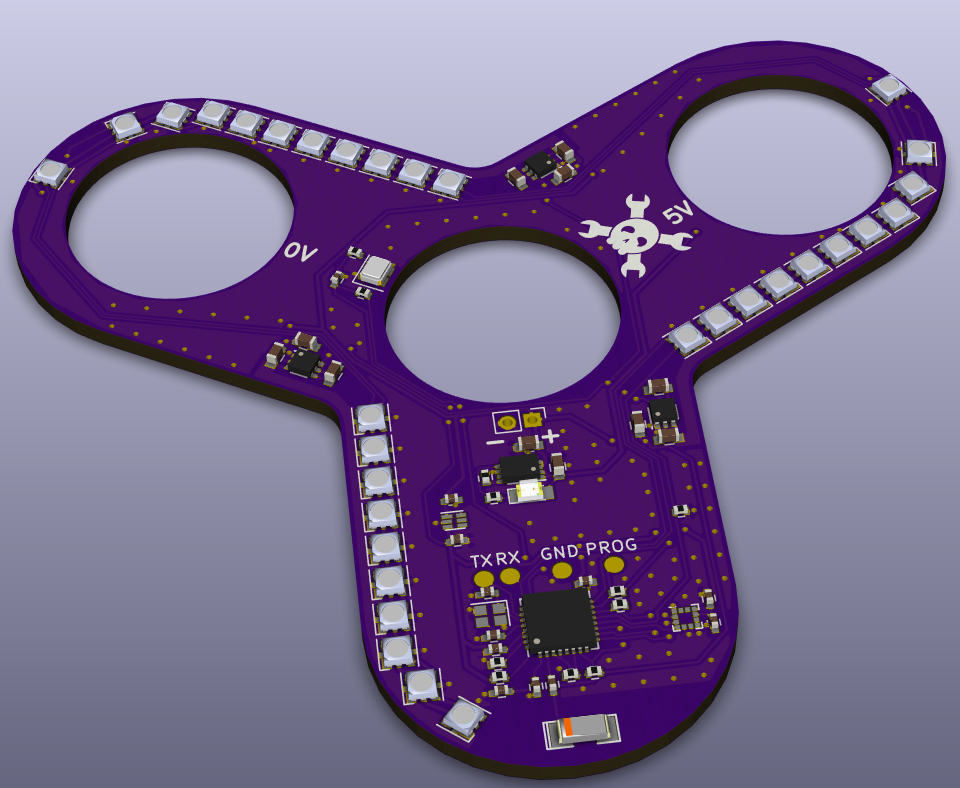

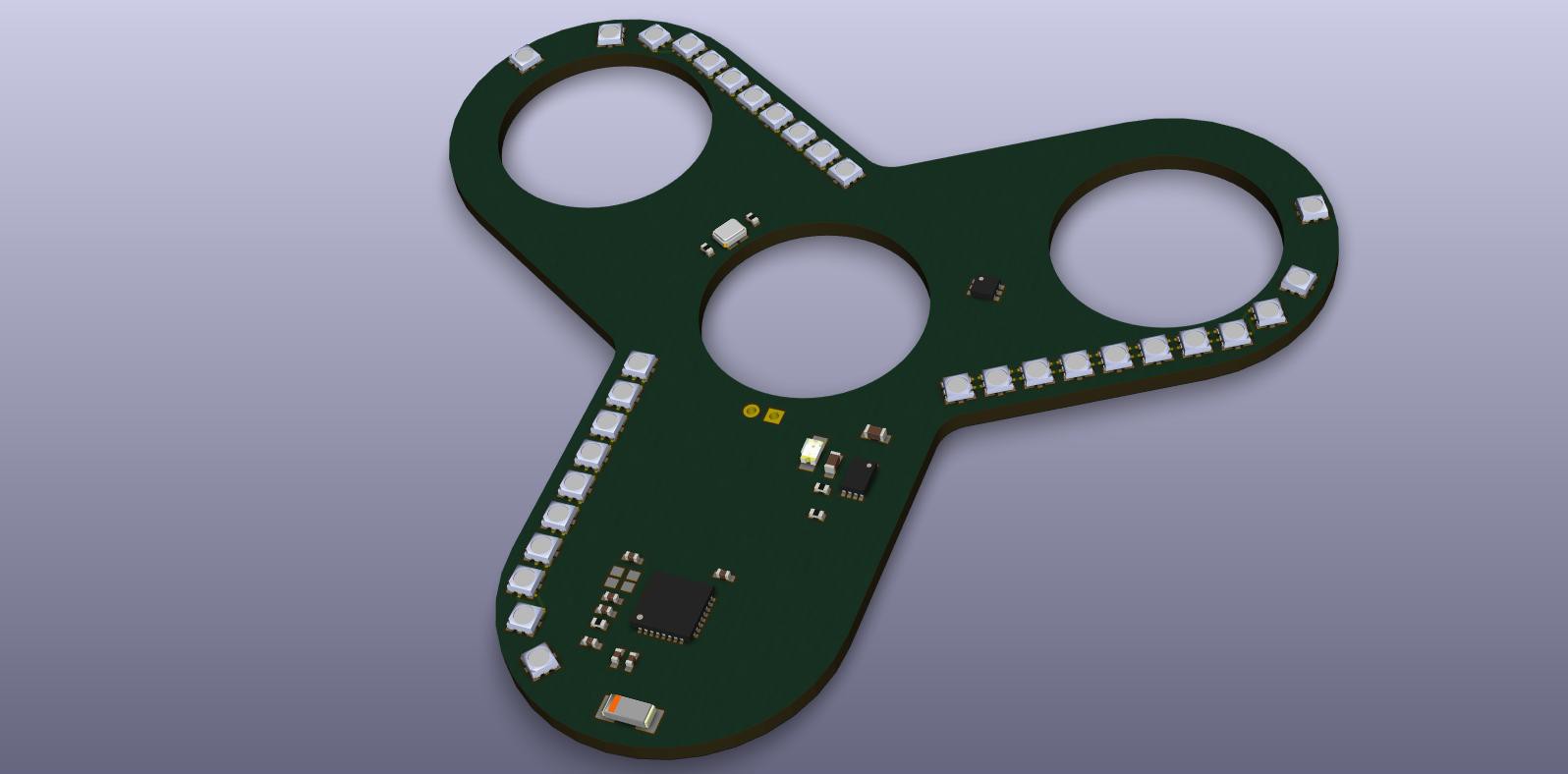

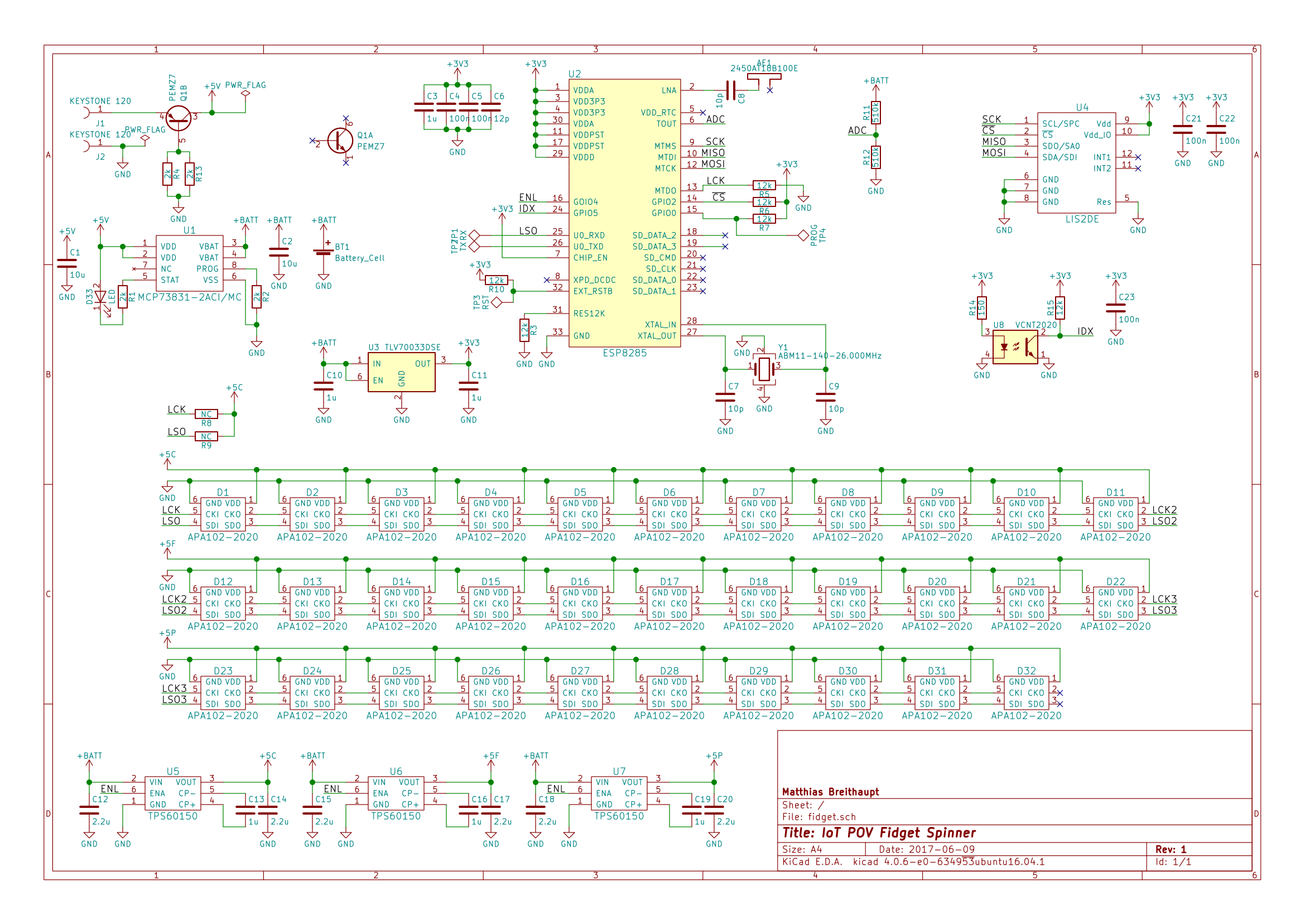

This addresses multiple challenges at once: How do you improve fidget spinners? How do you combine them with electronics? Can you turn them into useful IoT devices? Can you add more buzz words (most challenging - Arduino?)?

First of all, it allows you to display messages and maybe pictures on your fidget spinner. That's should already be world changing enough on its own. But wait! That's not all! You also gain the ability to compete with the spinning ability of others by comparing your stats (rpm, duration). And you even get to see how balanced your spinner is using the integrated accelerometer and possibly find out how to improve the balance (using the accelerometer is somewhere further down the priority list, though).

Unless otherwise noted, everything is GPLv3. The git repository comes with a license file.

Matthias

Matthias

Matias N.

Matias N.

Xasin

Xasin

Arthur Admiraal

Arthur Admiraal

Quick question: are you interleaving your apa102 LEDs? I wasn't planning to, but now that I'm looking at the form factor for the pcba I can't pack in quite as many as I'd hoped despite how tiny they are. I'm considering interleaving them by offsetting their radial distances by a half pitch on the other arm (mine is planned to be a 2-arm spinner). However the actual led locations are not the center of the package so some thought might need to go into placement.