How does the first iteration work?

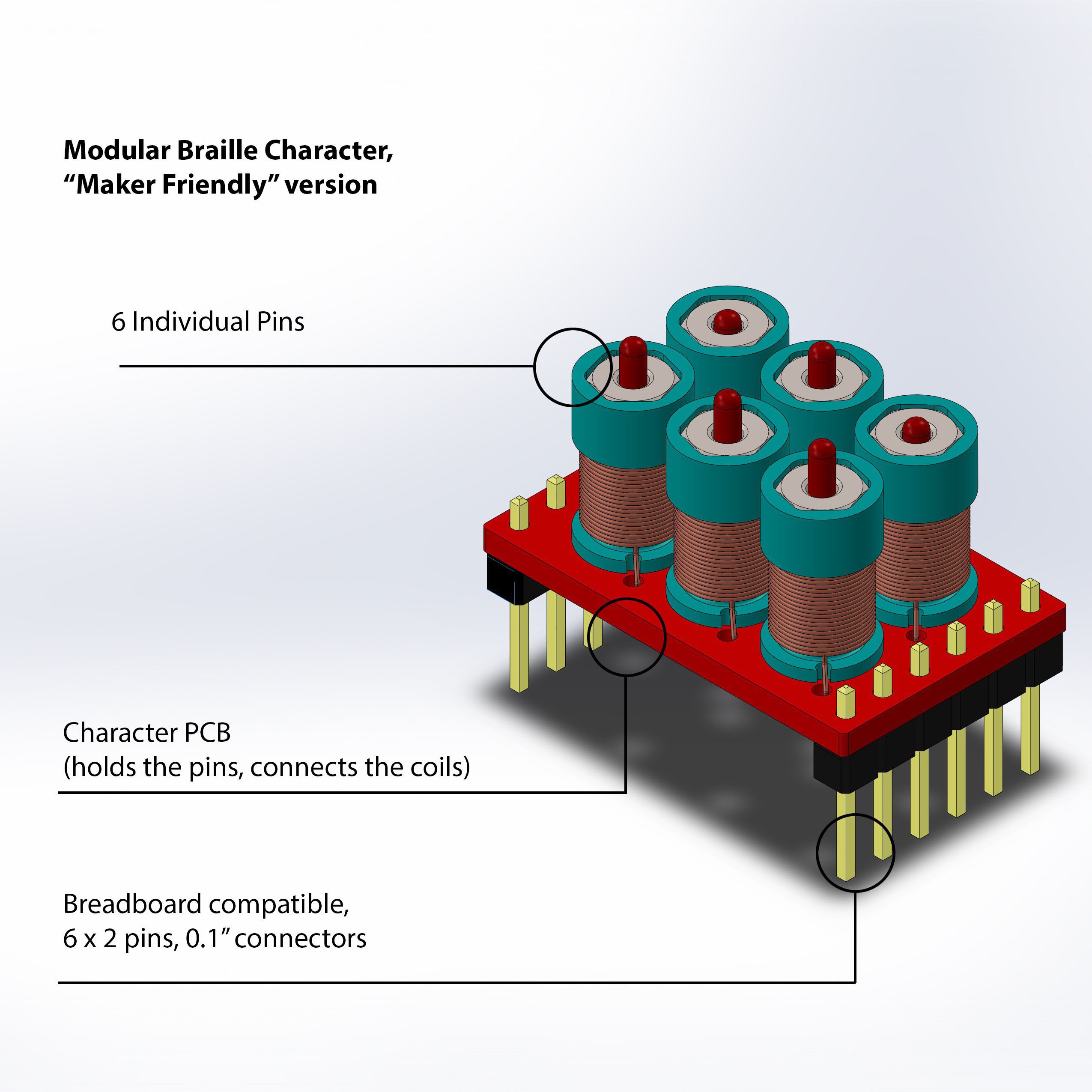

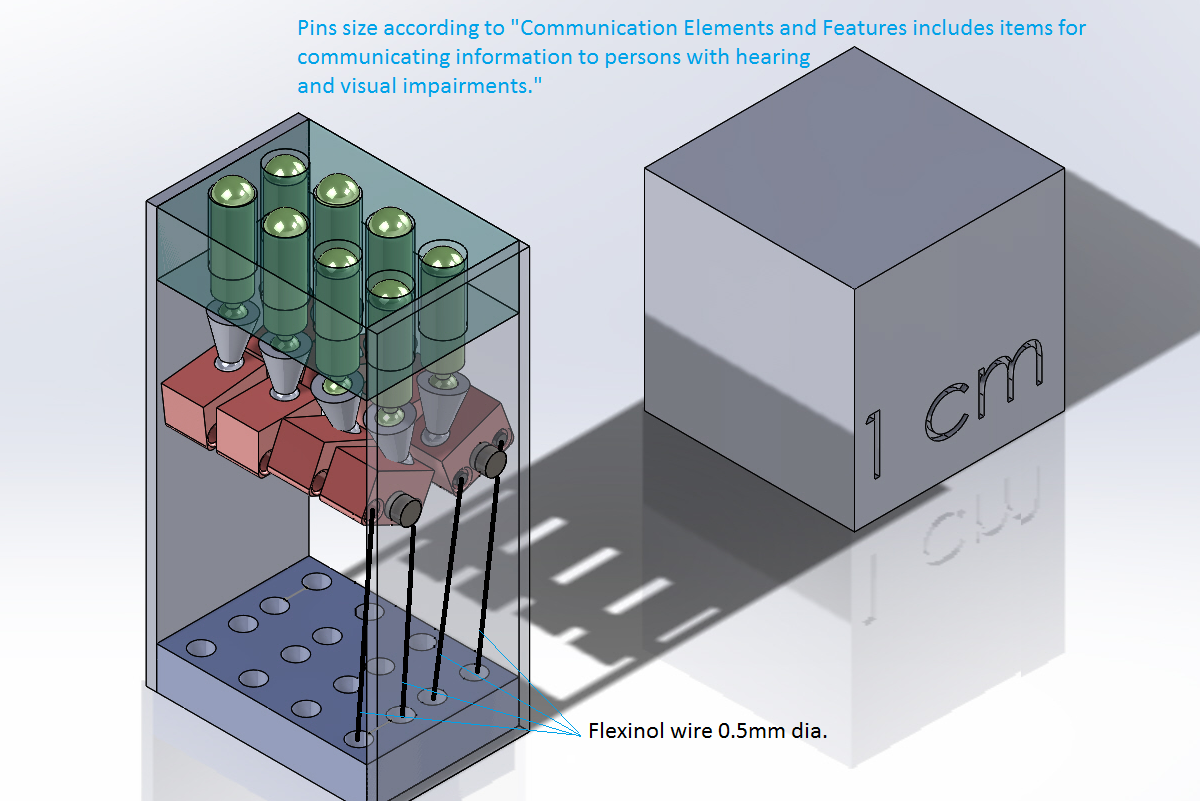

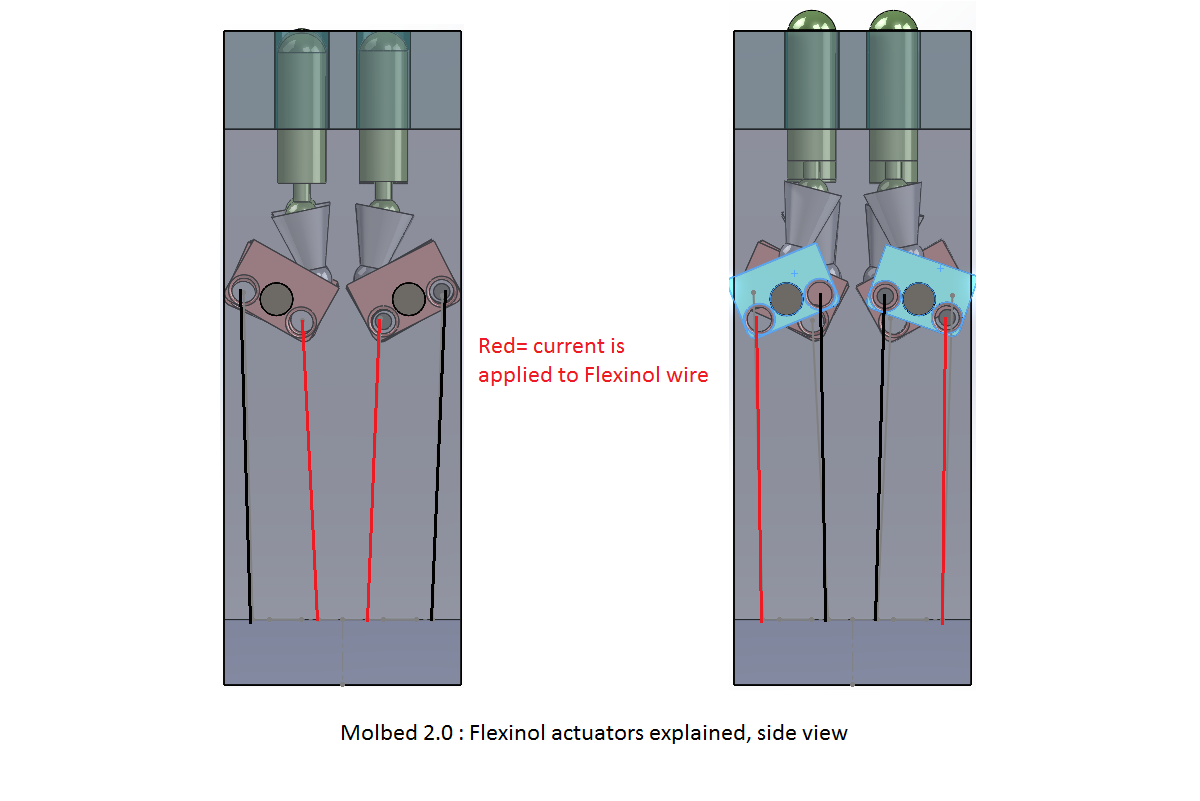

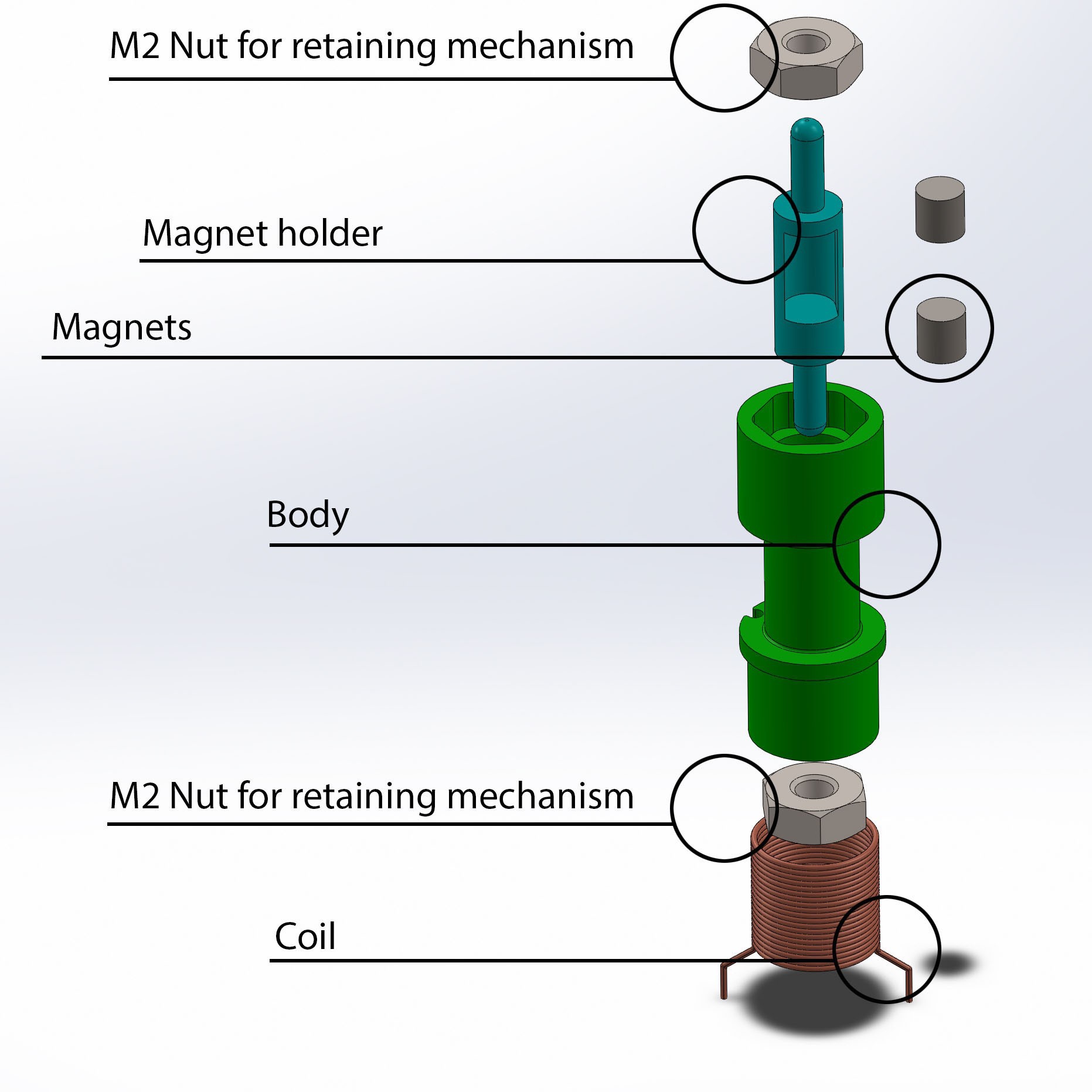

With the current design, each "dot" on a character module is made up of 2 3D printed parts (Body and Magnet holder), 2 M2 nuts, 2 magnets, and 0.1mm enameled wire. A controlling PCB also hold the bodies. This design uses a really low parts count, and efforts have been put to use parts already available, such as the M2 steel nut; this design allows for a very low cost per character.

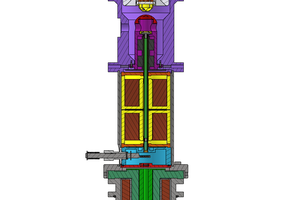

The first prototype, that was able to show some words in Braille, one character at a time:

The testing characters were working well; finding the perfect balance was still under progress, and a lot of optimization of the pins has yet to be done.

Three different testing boards were made designed as Arduino Uno Shields, for easy testing of the characters. Two of them have a small embedded Oled display for showing the corresponding letter and debugging. I even designed a 3d modeled cover for it ;)

Madaeon

Madaeon

The first prototype has been tested thanks to the Italian association for visually impaired people.

The first prototype has been tested thanks to the Italian association for visually impaired people.

zapwizard

zapwizard

Brien Allison

Brien Allison

Vini's Lab

Vini's Lab

NICE JOB!!! I am working on a project to help blind go without blind cane.