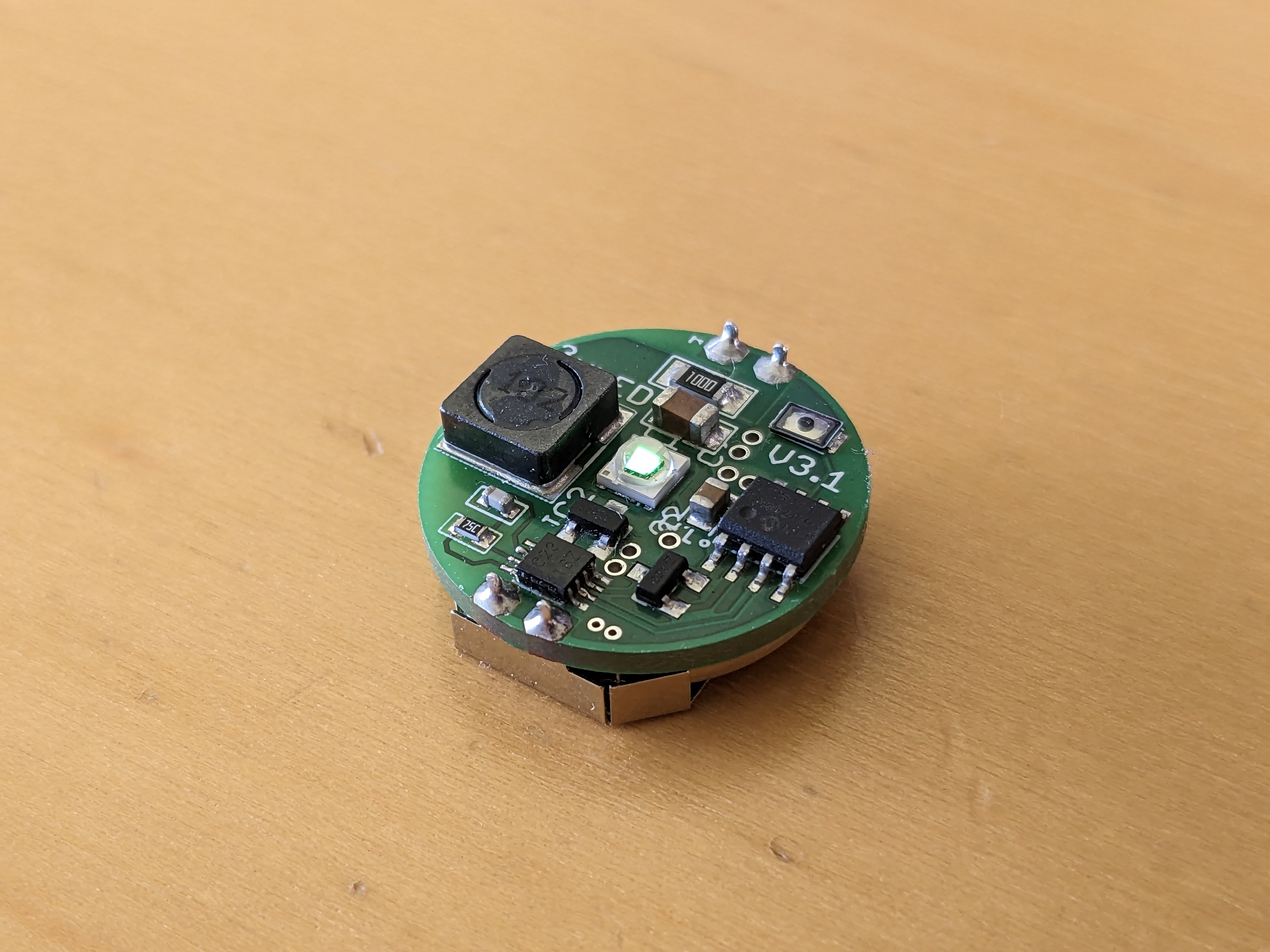

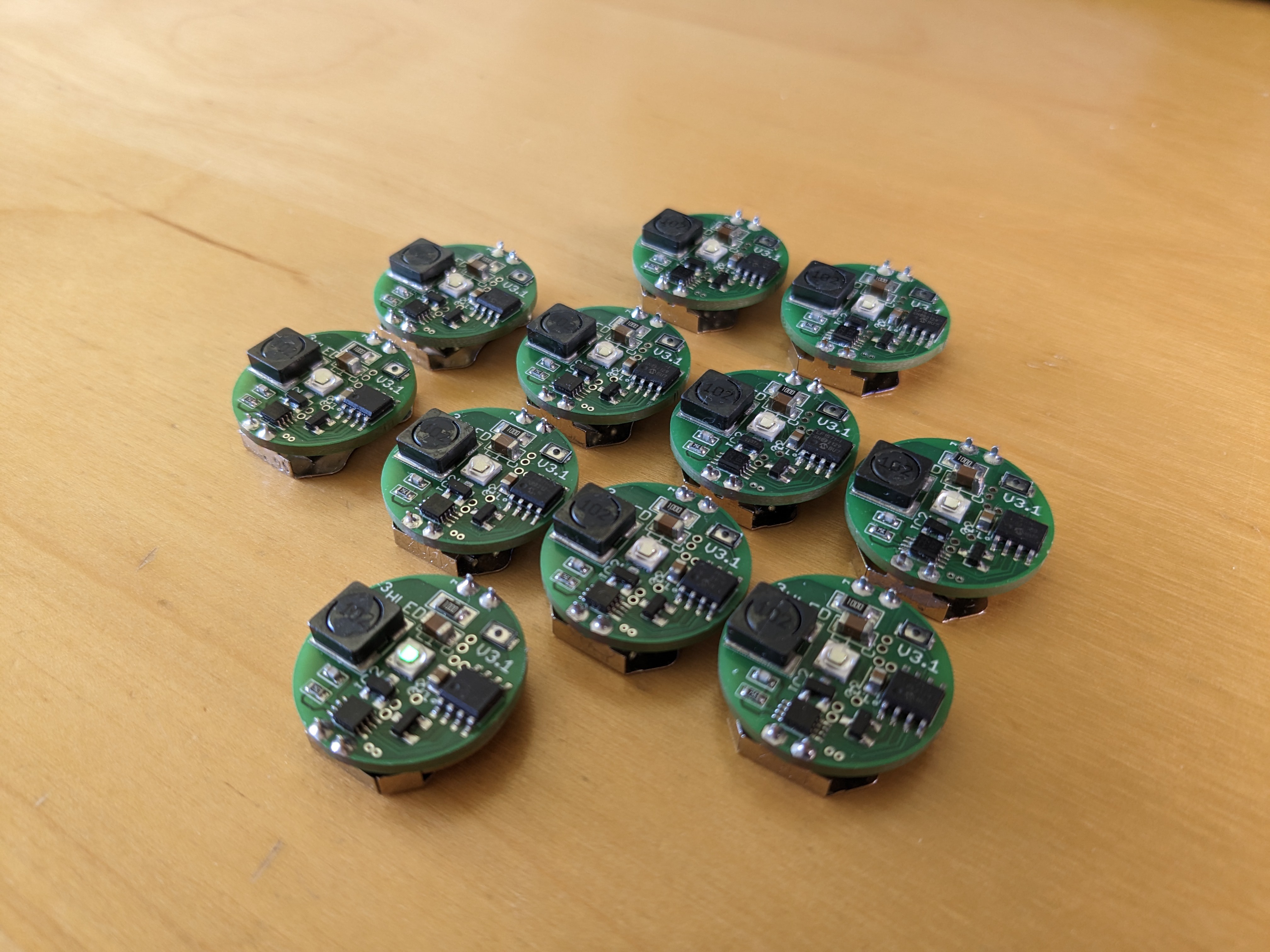

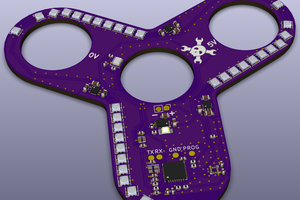

Since tritium light sources are hard to get in my country, I was looking for a more high-tech solution to finding my flashlight in the dark. Searching the internet, I found @Ted Yapo's project #TritiLED.

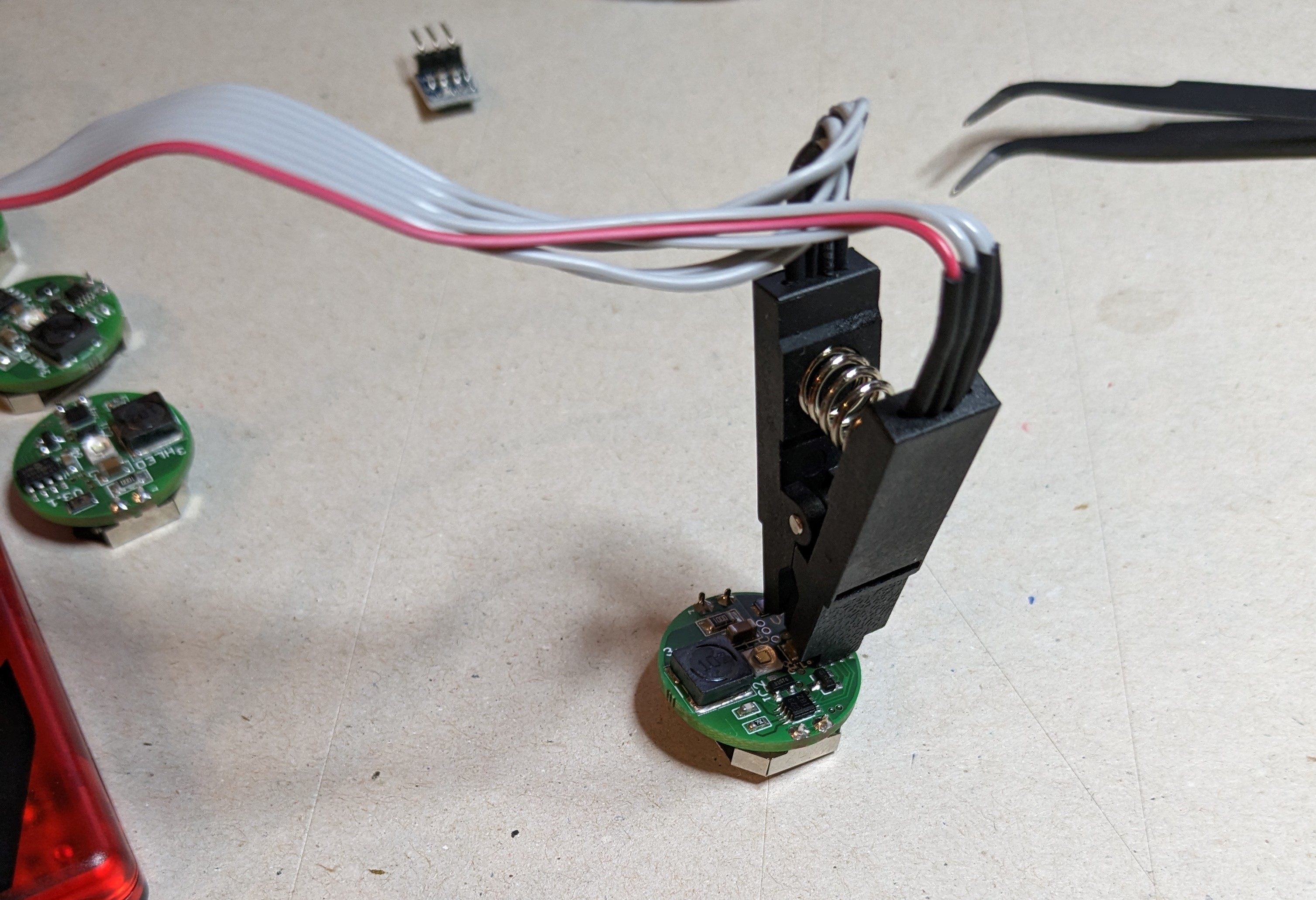

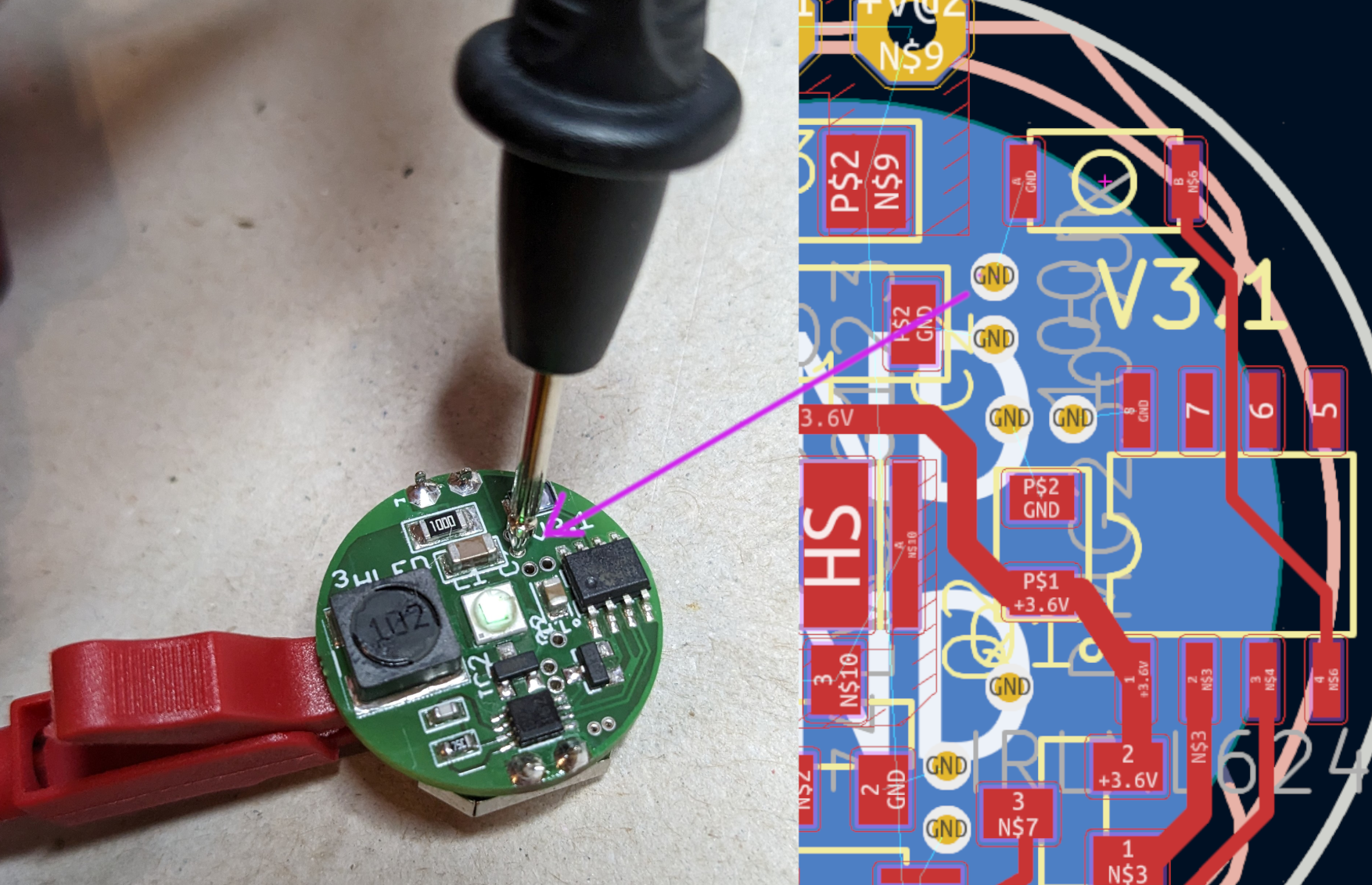

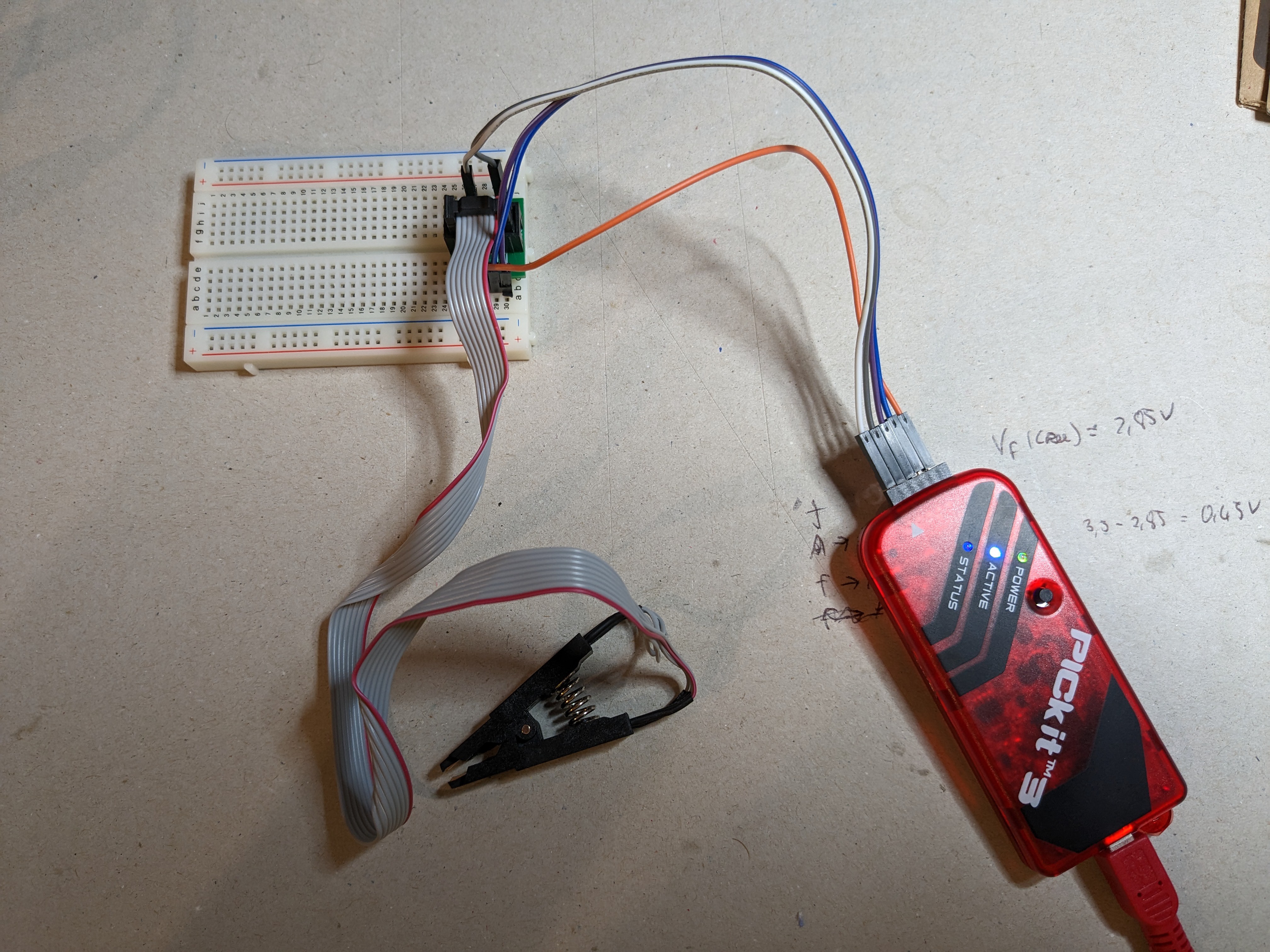

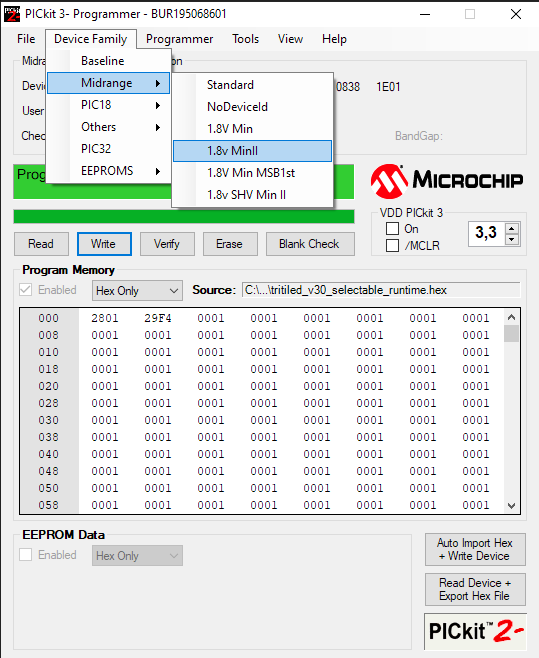

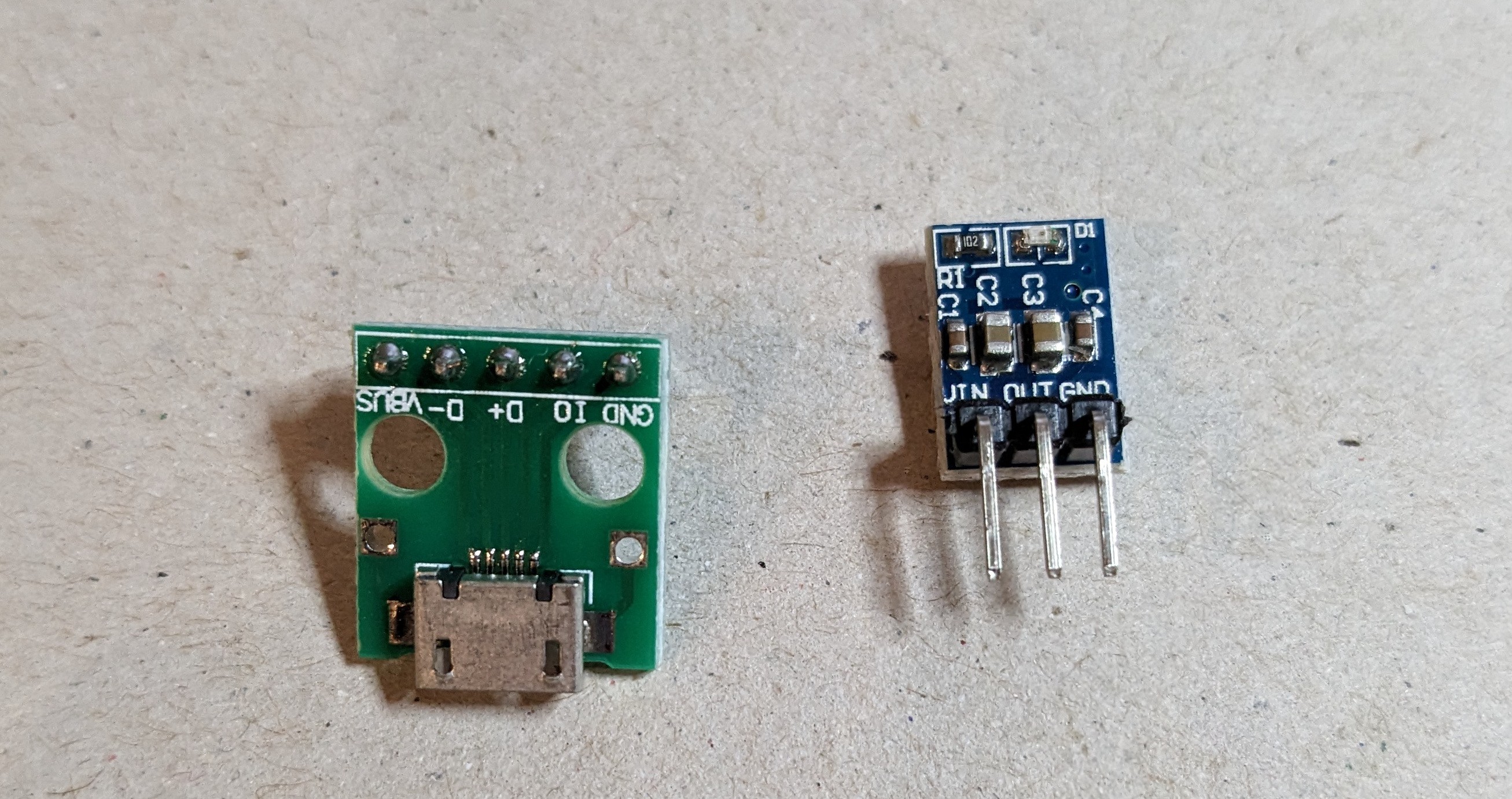

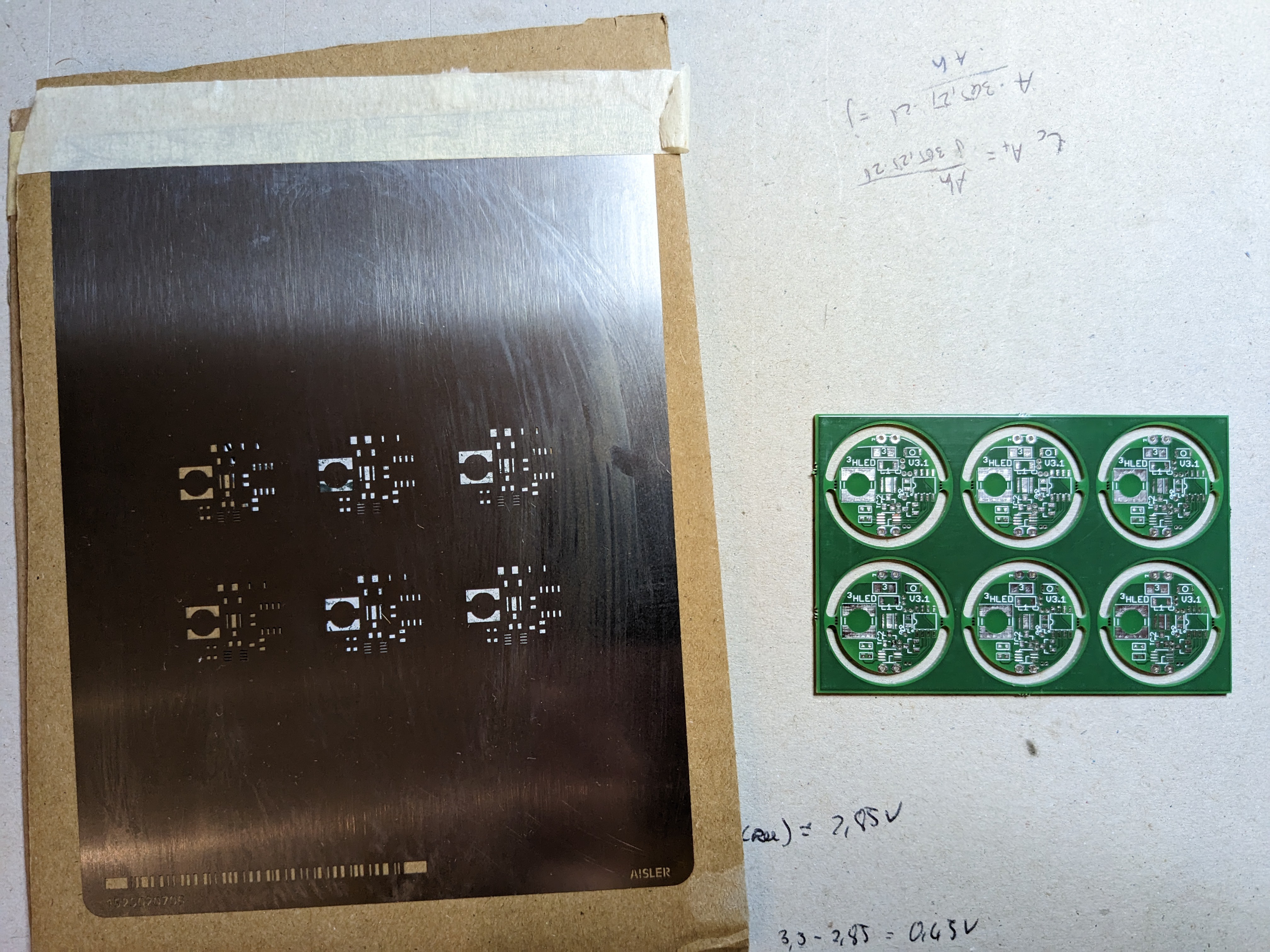

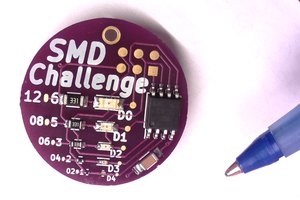

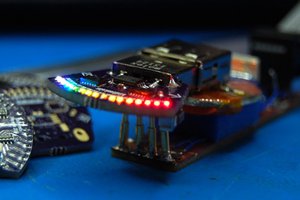

While his build logs are excellent, I was struggling with the more mundane aspects like programming a PIC microcontroller, and the required tool chain as well as SMD soldering. I'm writing about my learning process to document it for my future self and others that might have similar problems.

schlion

schlion

rrace001

rrace001

Matthias

Matthias

MakersBox

MakersBox

zakqwy

zakqwy